The Benefits of Plastic Outrigger Pads

The size of your plastic outrigger pad will depend on the weight of your equipment and the amount of sand on the ground. Make sure that you purchase one with ample surface area around it to distribute force evenly. When choosing outrigger pads, keep in mind that there are several reasons why you may want to have extras besides your main set. If you plan on expanding your equipment pool in the future, you might want to purchase extra pads so that you will have some spares.

One of the primary benefits of plastic outrigger pads is that they are lightweight, durable, and easily installed by one or two people. Furthermore, these pads are water-resistant and will not swell or absorb moisture, making them an excellent choice for outdoor applications. Furthermore, they are highly resistant to chemicals, corrosive materials, and heat. A good-quality plastic pad is designed to withstand a wide range of environmental conditions, and is guaranteed for life unless it is found to be defective.

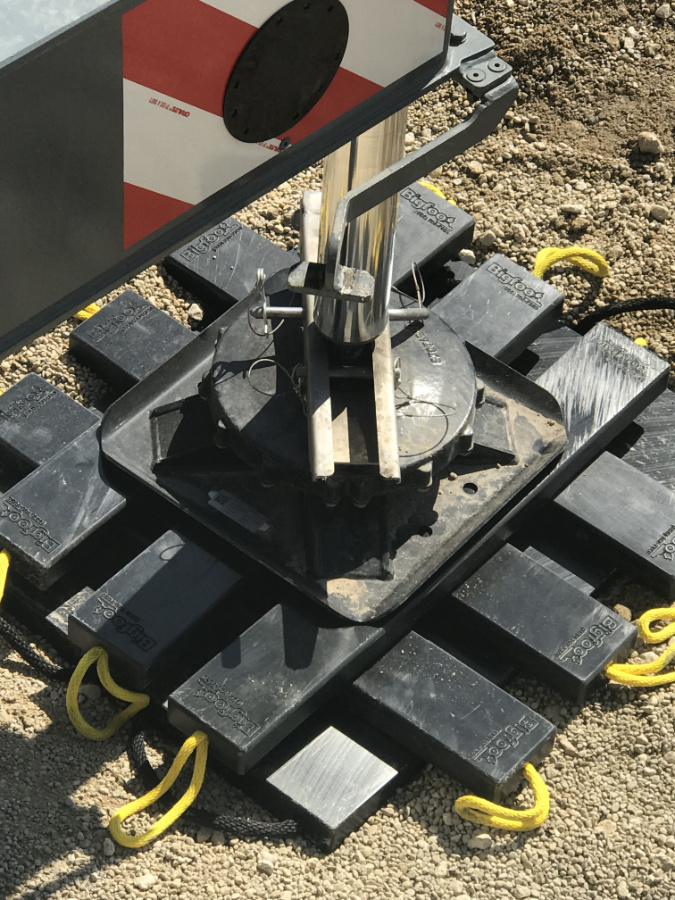

Plastic outrigger pads help stabilize mobile cranes and terrain outriggers. The center of mass of your equipment is the point at which it would balance if it were on a single point. The weight of an outrigger will shift the center of mass back over the footprint. The resulting movement will keep the outrigger stable and prevent it from falling or causing damage. Ensure that your plastic outrigger pads are rigid enough to prevent your crane from being pushed off level.

Another important feature of outrigger pads is their customisation options. In addition to providing non-skid surfaces, you can also opt for highly visible colours and even add company logos. When deploying an outrigger, it is best to sit in the middle of the pad. The middle position will evenly distribute the weight. You must also check the float of your outrigger, as a smaller float will cause too much pressure on the ground.

Plastic outrigger pads help stabilize heavy machinery and improve safety standards. Most heavy equipment comes with an outrigger, which is a stabilizing support that projects from the machine. However, if your equipment includes other supports, it will still need a pad. These are also lightweight and easier to install than traditional steel ones. Aside from adding support and shock absorption, plastic outrigger pads are also more convenient to install.

If you plan on purchasing plastic outrigger pads, you should consult a professional to find the right one for your specific needs. Shop bigfoot outrigger pads now from Prime Tech Pads. The best ones have been developed by professionals who understand the weight and ground bearing pressures of your equipment. Make sure that you choose a pad that is built from high-quality materials. Utility Products offers DICA outrigger pads. You can also subscribe to Equipment Showcase to learn more about their range of products.

While installing outrigger pads, it is important to keep in mind that they are designed to support the maximum load that your pick can safely handle. When you are installing your new pad, be sure to check for any hidden voids or shallow pipelines that can interfere with your installation. Then, test it out by swinging a boom over the outriggers. If they sink, they need to be swung up a little to improve the ground condition.

For the most part, plastic outrigger pads, and bigfoot outrigger pad are more durable than wood outrigger pads. They are also more affordable. Wood outrigger pads tend to rot or splinter over time. They also hold moisture, so you need to replace them more often. Steel and aluminum outrigger pads are also costly to purchase and require frequent maintenance. They also tend to discolor and corrode, and they can become unreliable.

Wooden outrigger pads are cheap and easy to source, but they have several disadvantages. Industrial plastic outrigger pads are constructed of tough polymer called UHMW or ultra-high molecular-weight polyethylene. Both wood and plastic outrigger pads are constantly exposed to groundwater and potential contaminants such as road salt and motor oil. Because of the increased exposure to moisture, wood outrigger pads are prone to breaking and deterioration.