How PCBasic Manages Component Sourcing to Avoid Shortages and Reduce BOM Risk

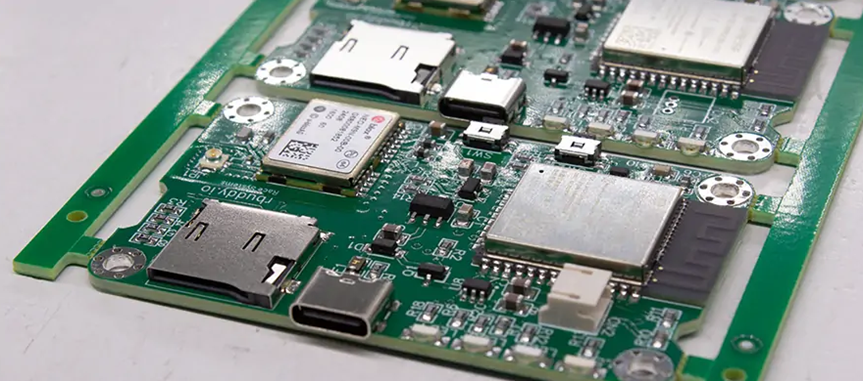

In today’s fast-paced electronics industry, working with a reliable PCBA manufacturer and ensuring accurate PCB prototype iterations are essential to maintaining production continuity. At PCBasic, component sourcing isn’t an afterthought — it’s a strategic capability that directly prevents part shortages, minimizes BOM risk, and protects customers from unexpected delays and cost escalations.

Table of Contents

Strategic Supplier Diversification

One of the most effective ways PCBasic avoids component shortages is through supplier diversification. Rather than relying on a single source for every part, PCBasic maintains a broad network of vetted global distributors, authorized manufacturers, and trusted franchised channels. This multi-source approach ensures that if one supplier experiences stock outages, alternative pathways can be activated quickly — keeping production moving without compromise.

Real-Time Market Intelligence

Component markets shift rapidly. Prices fluctuate, lead times expand, and sometimes entire part families become constrained due to demand spikes. To stay ahead, PCBasic invests in real-time market intelligence tools that monitor inventory levels, pricing trends, and forecast risk. By capturing this data continuously, the sourcing team can predict disruptions before they occur and take preemptive action to secure parts at optimal timing and cost.

Proactive Forecasting & Planning

Rather than react to shortages, PCBasic emphasizes proactive forecasting. Working closely with clients during the design and quotation phase, the team gains early visibility into expected volumes, variant requirements, and long-term program schedules. This early engagement enables intelligent forecasting — reserving critical components well in advance and advising customers on high-risk parts before they become emergencies.

Component Alternatives & DMSMS Mitigation

When ideal parts become constrained, PCBasic’s engineering and sourcing departments collaborate to identify suitable alternatives. This doesn’t mean settling for any component that “sort of fits,” but rather conducting rigorous electrical and mechanical evaluations to ensure form, fit, and function remain intact. Such proactive obsolescence and diminishing manufacturing sources and material shortages (DMSMS) management minimize BOM risk while preserving product integrity.

Inventory Buffering & Safety Stock

In high-risk categories — such as semiconductors, RF modules, and specialized passive components — PCBasic implements strategic inventory buffering. This means building safety stock based on risk profiles, lead time volatility, and customer production plans. While carrying higher stock has a cost implication, this controlled buffer significantly reduces the likelihood of last-minute sourcing crises that derail production schedules.

Supplier Partnerships & Forecast Sharing

A foundational element of PCBasic’s sourcing strategy is its collaborative supplier relationships. By sharing forecasts and production projections with key distributors and manufacturers, PCBasic strengthens its standing in priority queues. Suppliers who view PCBasic as a reliable partner with transparent demand signals are more likely to allocate scarce inventory ahead of competitors — a clear advantage for customers with tight delivery expectations.

Digital BOM Management

PCBasic leverages BOM management systems that automate validation, lifecycle tracking, and alternates mapping. These digital tools enable systematic tracking of part status, obsolescence flags, and supply health. When a component begins to show risk indicators, alarms trigger proactive sourcing reviews, and recommended alternatives are preloaded into quotes and design considerations.

Continuous Communication with Customers

Effective sourcing isn’t just internal — it extends to customers. PCBasic maintains transparent communication channels, sharing component risk insights, lead-time changes, and alternative recommendations early in the process. This collaborative approach allows customers to make informed decisions about design changes, acceptable substitutes, or schedule adjustments — reducing surprises and building trust.

Conclusion

Component shortages and BOM risks are universal challenges in electronics manufacturing, but they’re not unavoidable. Through strategic supplier diversification, real-time market data, proactive forecasting, strong partnerships, and intelligent inventory management, PCBasic ensures customers benefit from smooth production cycles and resilient supply chains. When you choose PCBasic as your manufacturing partner, you’re choosing more than assembly — you’re choosing strategic component sourcing that protects your schedule, your budget, and your product success.