Cold cutting: when waterjet cutting is the safest option

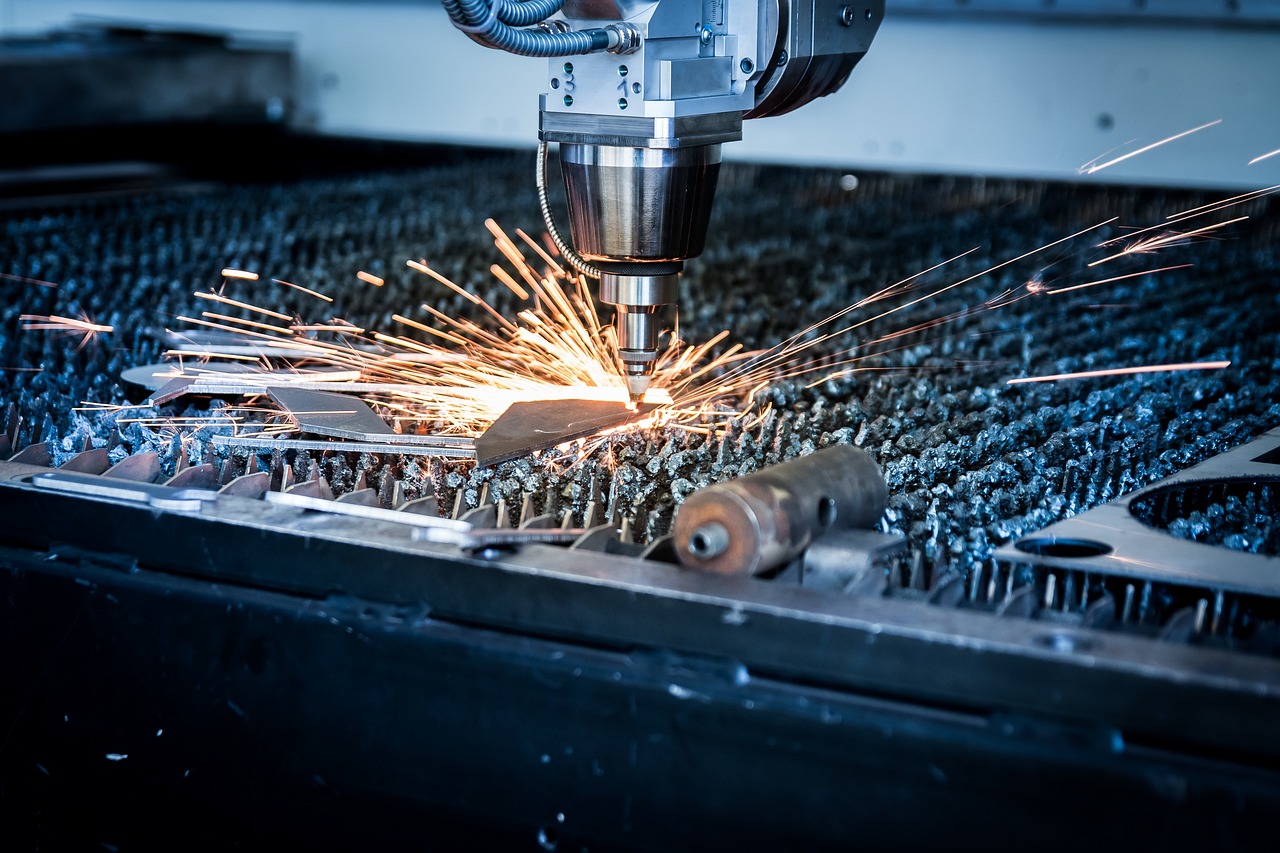

In an industrial context where precision and safety are paramount, cold cutting has emerged as one of the most reliable solutions. Unlike thermal techniques that produce heat and sparks, high-pressure water jets allow materials to be processed without deforming their structure, thus reducing operational risks. This technique is increasingly favored in demanding sectors such as aerospace, metallurgy, and construction. In this guide, we explain the principle of cold cutting and the advantages that distinguish it from other approaches.

Table of Contents

Understanding the principle of cold cutting

Cold cutting relies on the use of a high-pressure water jet capable of passing through various types of materials without producing any heat. This approach contrasts sharply with découpage laser , which uses thermal energy to work materials, potentially creating hot spots and causing deformation.

Waterjet cutting allows for the creation of parts using the mechanical impact of a powerful stream, capable of reaching several thousand bars. This process preserves the material’s structure and achieves extremely precise finishes. This method is also distinguished by its flexibility depending on the type of material being treated. For soft materials, the technician can use pure waterjet cutting. Conversely, hard materials such as metal or stone are treated with waterjet cutting mixed with an abrasive.

Thanks to its flexibility, modernity, and precision, cold cutting allows for the creation of complex shapes, fine contours, and clean, burr-free internal cuts. All these advantages make it a superior choice for sectors demanding a high-quality finish, extreme precision, and optimal safety.

The advantages of waterjet cutting

Cold cutting is a method that appeals due to its versatility and its ability to preserve the structure of the worked pieces. But that’s not all! It offers many other advantages in several areas.

A method that preserves the integrity of the materials

Waterjet cutting is considered the safest solution for preserving the purity of materials. Unlike plasma or laser cutting, it does not generate heat during operation. Consequently, it minimizes any risk of burning or material degradation. This technique is particularly recommended for sensitive materials such as plastics or composites that can easily deform under thermal effects.

Thanks to its completely cold operation, the water jet protects the molecular structure, ensuring the stability and durability of the manufactured part. By controlling the ambient temperature, this technique not only preserves the integrity of the materials but also protects surrounding machinery.

A process that can be applied to a wide variety of materials

One of the most remarkable advantages of waterjet cutting is its ability to adapt to a wide variety of materials. With this technology, technicians can work with metal, stone, glass, rubber, ceramics, wood, composites, and even food with impressive efficiency. Its high water pressure, whether used alone or in combination with an abrasive, can penetrate both soft surfaces and hard materials.

Thanks to its versatility, there’s no longer a need to align tools in the production line. This saves technicians time and frees up significant space in workshops. It’s also a solution that allows companies to achieve substantial cost savings.

A technique that guarantees a flawless finish

Waterjet cutting is an approach that demonstrates finesse and precision on the material’s surface. It allows for clean edges that require no further finishing before use. This precision in material processing reduces the number of steps, saving time and optimizing production costs.

The resulting parts are free of any spatter or imperfections. They offer a uniform surface, which facilitates assembly. This method is particularly valued by industries seeking immediately usable cut quality without further intervention. By minimizing rework, waterjet cutting guarantees flawless designs from the very first cut. This increases production flow and therefore optimizes output.

An approach that reduces the risk of fire

Waterjet cutting is the most reassuring technique in terms of safety requirements. As mentioned above, it does not generate heat, which limits the risks of flames and sparks. Its operation with only pressurized water eliminates any threat of fire or explosion. This is a crucial factor in sensitive areas such as metalworking shops, chemical plants, or facilities where flammable products are manufactured.

Furthermore, this technology is perfectly suited to industrial automation thanks to its digital operation. It integrates modern equipment such as les machines Spark & Co , which can be programmed to reproduce cuts identically and at high production speeds. This automated production system optimizes consistency while significantly reducing human error.

Industrial applications where water jet is the best solution

Waterjet cutting is used in any industry where safety standards are strict. In the aerospace industry, this method is suitable for cutting materials that cannot withstand heat, such as carbon composites, lightweight alloys, and multilayer materials. Unlike thermal methods, this technique preserves mechanical properties, an absolutely crucial factor for ensuring the performance of aerospace components.

In the petrochemical industry, where flammable gases, oils, or solvents are present, this solution is preferred for its cold operation. Its ability to cut materials without the risk of flame or heat ensures safety and makes work safer for technicians. They can perform maintenance and replace equipment without fear of danger.

In the building and decoration sector, the absence of heat prevents cracking and chipping. This allows craftsmen to make complex cuts, create custom designs, or perform assemblies without risk of damaging the material.