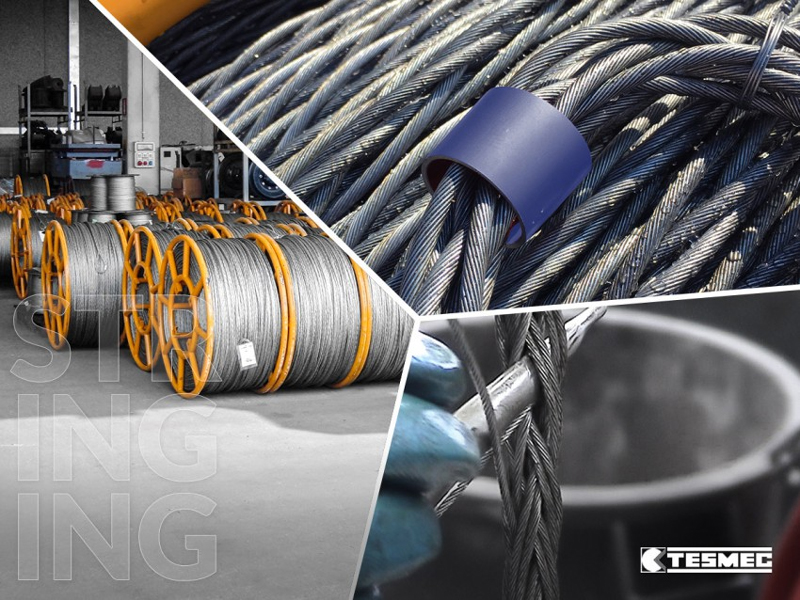

Anti-twist wire rope is used to track and guide conductors to pass through rivers and mountains

Rotation-resistant anti-twist wire rope refers to a series of steel ropes that minimizes the inclination to spin under the load. These wire ropes boast a special design that is, the outer layer is twisted in the opposite direction of inner layers for counteracting torsional forces made from multilayer strands.

Table of Contents

Layers of strands:

To achieve resistance against the spin and rotation, all anti-twist wire rope are made of two layers of strands. In general, the more layers a rotation-resistant wire rope has, the more resistance it will boast. For example, a two-layer rope is much easier to spin and rotate than a three-layer rope. In the meantime, if one end of the free rotation is allowed, the 2-layer rope can only develop 55% of its breaking strength compared with 95% of 3-layer ropes. Conferring to features of rotation resistant wire ropes, 3 categories are supplied by our company to suit different needs. Normally two-layer spin and rotation resistant wire ropes can meet all the needs of low and medium resistance. The three-layer rope with more outer strands is accomplished to distribute more radial pressure onto inner layers and is ideal for larger mobile such as all tower cranes.

Application:

- They can Serve as single part lines.

- In whip hoist ropes.

- In Deck crane ropes.

- In Offshore crane ropes.

- In Pillar crane ropes, etc.

Details of anti-twist wire rope:

The details of anti-twist wire rope are as follows

- Surface: It has a bright or galvanized finish.

- Lay style: It has a regular or lang lay as your requirements.

- It is Available with plastic impregnated.

- Outer strands: It has 5 to 20 strands.

Product Description

These Anti-twist Wire Ropes are braided with fine zinc plated wires. It is Square or hexagon in shape which is braided with 4-strand, 6-strand, or 9-strand twisting with each other either leftwards or rightwards. It is relative to the section. The twisting force on the section can be unconfined with each other whether it receives a force or not. The instant of twisting is nothing for the wire rope.

Applications:

The special braided steel wire rope is extensively used in power line stringing operations, in pulling conductors, in OPGW cable, in ADSS, and in 500kv traction rope, etc. Wire ropes with 8 strands & two-layer constructions without twisted inner strands have a very similar appearance to rotation-resistant wire ropes, but they are not. Rotation-resistant wire ropes are measured to be less stable need to be handled and connected with great care. They must be taken to dodge high loads with small diameter sheaves. To avoid lay turbulences of the outer strands, it is optional to ensure ends of the rope are grabbed tightly or brazed.

Non-Rotating Wire Rope

Rope Services Direct has a variety of anti-spin non-rotating wire ropes also called rotation resistant wire rope. All standard rope wire inclines to develop torque and so prone to rotation, while non-rotating wire ropes are intended so that the wire rope’s outer rotational force counteracts the inner strands of the rotational force.

Why use Non-Rotating Wire Rope

The rope elongation and rotation happen on standard ropes when loaded, which can consequently spin the load, quite probably out of control, which can be unsafe. When the rope switches in this way the strands will begin to undo. This causes the rope to lose its strength and will fail, which could be disastrous. It is for these reasons that nonrotating wire rope is usually used for many types of lifting applications including the main hoist rope, crane rope, and deck rope.

Characteristics of Anti-Spin Rope

Non-rotating wire rope or rotation-resistant wire rope has a dissimilar construction to standard. as all the wires and strands are not laid in the same direction as they would be on the standard rope. The inner and outer strands of wires are placed in opposite directions. For example, the inner may be built-in left hand lay at the same time as the outer layer is in right lay. The landscape of this construction means that torsional forces on both the inner and outer strands will counteract each other and therefore minimizing the risk of unraveling. A 2-layer rope has less resistance than a 3-layer rope. So, the more layers the rope has the better rotation resistance it will have. These types of ropes can be divided into spin-resistant rope, rotation-resistant rope, and non-rotation-resistant rope. Classed based on the number of rotations a firm length of rope does when a force of 20% of the force is applied; with one turn or less the rope will be classified as nonrotating; with rotations between 1 to 4 the rope is classed as low rotation rope and for rotations between 4 to 10 the rope will be classified as spin resistant rope, any higher and the rope then it is not rotation resistant at all.

Care & Handling

Correct usage and care with treatment will prolong the working life. This is due to the resistance on the inner wires caused by the strand crossover which will finally cause the inner wires to break up. This is more apparent on non-rotating wire rope with 2 layers. Ropes with three or more strand layers will allocate the radial pressures more evenly which will decrease friction and pressure on the inner wires. Regular, thorough reviews of non-rotating rope are important since it is the inner strands that frequently break first and broken internal wires often go ignored as they are difficult to see. Rope Services Direct offers checks on all rope with certification issued if there is any completion. The rotation-resistant rope should evade shock loading. This is because rope misrepresentations and core protrusion can occur. Holding both the ends of the rope will prevent unraveling. Properly fitted terminations will help to stop damage. Kinking and unraveling may often occur and they can also have a consequence on the rotational balance if they are not fitted correctly.